PTFE Envelope Gaskets

A Pioneer in the field of Industrial PTFE Envelope Gaskets, Jain Mill Stores is a specialized in Manufacturing of PTFE Envelope Gasket. consists of an envelope of PTFE with CAF/CNAF Insertion. The envelope gasket is normally used as a flange gasket in industries where there is a necessity of high chemical and pressure resistance. PTFE Envelope Gasket is chemical resistant and have Wide temperature range thus combining the benefits of different materials.

We at Jain Mill Store supply PTFE Envelope Gaskets according to all standard sizes for flanges. We can also provide customized envelope gaskets according to your Requirements.We are specialized in manufacturing, supplying and exporting of PTFE Envelope Gasket that is procured using one of the finest resources available.

PTFE ENVELOPE GASKET with AF 120 Non Metallic Insertion, Ring Type #150

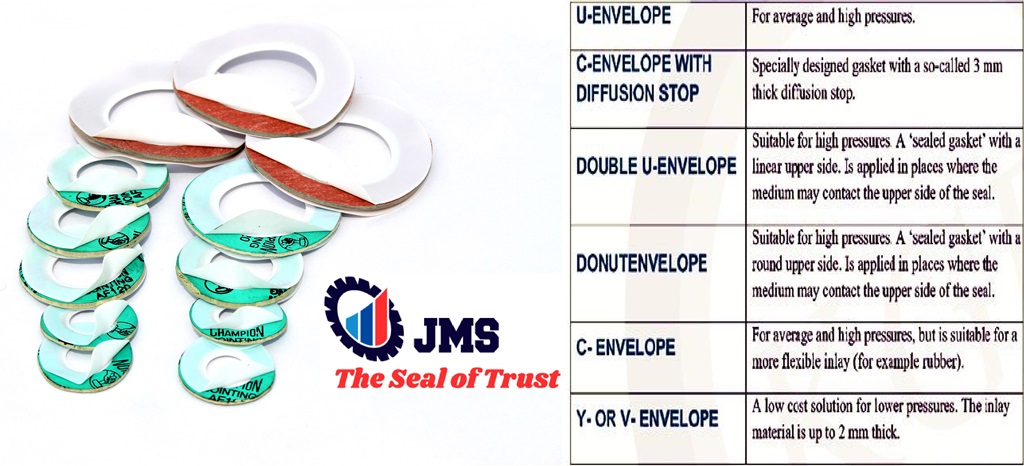

Jain Mill Stores foremost suppliers of excusive range of PTFE Envelope Gasket, which are developed using quality PTFE material, JAINCO PTFE Envelope Gasket manufacturing from PTFE Envelope, Non Asbestos and Asbestos Insert and SS Ring with various thickness are available which is use for Glass Lined Reactor Nozzle Flange and Manhole Nozzle Flange, Our PTFE Envelope are C Type, V Type and other different size available.

These are also customized as per the exact specifications of our valued Customers. We supply PTFE envelope gaskets in various types, such as:

Our special ring gaskets, PTFE cut gasket, PTFE solid ring gasket are available in 1.5 mm, 2 mm & 3 mm, 4 mm, 5 mm thick. Gaskets are manufactured to suite different flange standard like; E/F table, ANSI B16.20 – B16.5 – 150#, 300# & 600# flange, Raise face & full face PTFE gaskets are also available as per client drawing specification.

PTFE Envelope Gasket are widely used in Food Processing, Pharmaceutical, Chemical, and Petrochemical industries because of their excellent Ability to withstand properties to ensure operational safety and product purity.

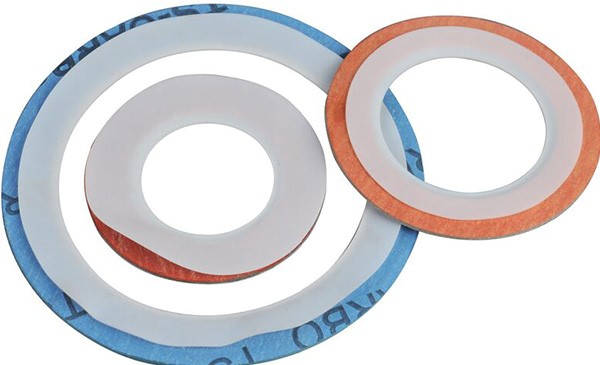

PTFE Envelope Gaskets are widely used in food, pharma, chemical, and petrochemical industries because of their excellent resistance features to ensure operational safety and product purity. We serves reputed clients in these industries as respected PTFE envelope gasket suppliers as well as gasket manufacturers. The envelope gaskets are available with metallic rings and non-metallic inserts as per the client requirements.

The PTFE envelope gasket from Us, one of the notable PTFE envelope gaskets manufacturers, is produced in accordance with the international safety standards including FDA regulations depending on the desired application. The quality assurance of German engineering can be experienced in the product range offered by us as well.

- Very good media resistance with the exception of liquid alkali

- metals and some fluorine compound

- Suitable for increased requirements in operational safety, tightness and product purity

- Long-term stable compression and recovery characteristics

- PTFE is physiologically harmless for continuous operation temperatures up to 260 °C as per BG no. 21

- Low permeability towards gases and liquids

- Anti-adhesive surface

- UV and ageing resistant

- Good non-stick characteristics

- Excellent dielectric properties

- FDA-conform PTFE-envelope as well as non-metallic insert Complies with TA Luft 2002 [VDI 2440/2200] leakage requirements.

- For compounds with conductive pigment TFM 6221: Electrical conductivity, FDA-conform

- For designs with corrugated ring EMAIL US: Temperature resistance from -200 °C to 200°C [short term 230 °C]

- The cold flow and warm flow characteristics typical for PTFE is compensated by the superior recovery behavior even at high temperatures

- For aggressive media which is hazardous for the health

- Broad range of applications primarily in the chemical and petro-chemical sector

- Use in food sector and pharmaceutical production

- Used for high requirements in process purity

- Gasket systems for pipeline flanges, device and container flanges

- In steel pipelines:

- Gaskets with corrugated metal ring

- Gaskets with aramid fiber insert with/without corrugated metal ring

- Gaskets with PTFE insert with/without corrugated metal ring

- For glass lined pipelines, containers, nozzles and assembly openings as well as for low surface pressures, waviness and warping of the flange sealing surfaces and for sensitive flange surfaces, stress and bend sensitive flange connections:

- Gaskets with insert with/without corrugated metal ring

- Gaskets with PTFE insert with/without corrugated metal ring

- Design with corrugated metal ring for the use in steel pipe-lines,

- dimensions as per DIN EN 1514-1 and DIN EN 12560-1 or ASME B 16.21

- Design with non-metallic insert, dimensions as per DIN EN 1514-3 and DIN EN 12560-3 or ASME B 16.21

- Design with corrugated metal ring and non-metallic insert, dimensions as per DIN EN 1514-3 and DIN EN 12560-3 or ASME B 16.21

- With corrugated metal ring WS 7110/1.4571 PW-I; thickness: 3.5 mm

- With non-metallic insert WS 7110/3822; WS 7110/3825; WS 7110/7550;thickness: 4.0 mm

- With corrugated ring and non-metallic inserts WS 7110/1.4571/3822; WS 7110/1.4571/3825;WS 7110/1.4571/7550; thickness: 6.5 mm or in consideration of the design recommendation 8.5/10.5 mm

We offer Full array of services To Deliver One Stop reliability to counter all your needs. From Management to Production we are committed to excellence at all levels of services, operations and wide range of Industrial applications.

Our Company supplies various products to many industries all over country. We have extensive experience of working with Professionals and engineers to solve your problems, and to supply parts that meet accurate specifications. We manufacture all types of gaskets and seals, for a wide variety of conditions and environments.

Jain Mill Stores is unconditionally committed towards its customer’s satisfaction and success by consistently being transparent to establish mutual trust & understanding, ensuring timely delivery of all products as per customer’s need.